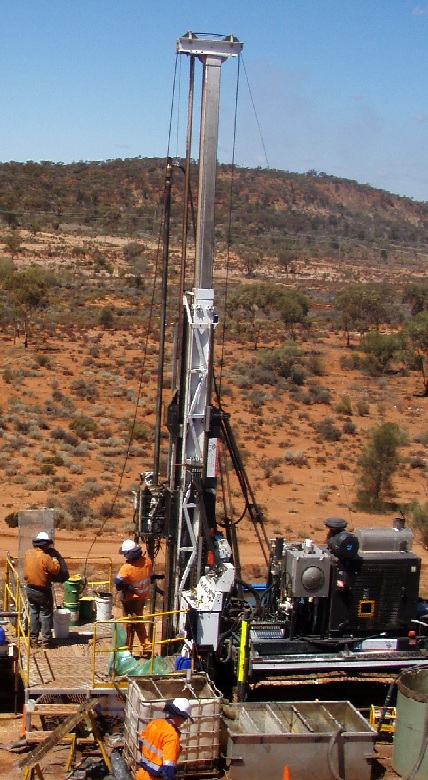

SURFACE Drilling

Our specialist equipment includes:

Diamond Drill - Platform Mounted LM90

Power unit - Cummins QSB 5.9L, Tier II, Turbo Charged, After Cooled, Diesel Engine

Power unit - Cummins QSB 5.9L, Tier II, Turbo Charged, After Cooled, Diesel Engine

FEATURES

- Pilot operated hydraulic controls for ease of service, including direct coupled hydraulic pumps, hydraulic rod making and breaking and levelling jacks

- Independant dual hydraulic mast raising cylinders

- Hydraulic telescopic mast extends to allow 9m rod pulls and 6m inner tube runs

- Capable of drilling -90° to +45° if deployed close enough to the rock face, or if up holes were required

- Hydraulic mast dumping capability up to 2340mm, for ergonomic use

- The platforms are self bundled, so no oils water or spills go onto the ground

- There is no need for sumps as our specially designed standpipe directs all return water into pods and a mobile sump on the platform

- Field proven, patented nitrogen gas spring Nitro Chuck

- 7,258kg capacity mainline hoist

Diamond Drill - Track Mounted LF90D

Power unit - Cummins QSB 5.9L, Tier II, Turbo Charged, After Cooled, Diesel Engine

Power unit - Cummins QSB 5.9L, Tier II, Turbo Charged, After Cooled, Diesel Engine

FEATURES

- Track mounted for all terrain mobility (remote controlled operation for safety)

- Direct coupled hydraulic pumps

- Hydraulic rod making and breaking

- Rod Sloop

- Pilot operated hydraulic controls for ease of service

- Independant dual hydraulic mast raising cylinders

- Hydraulic, telescopic mast extends to allow 9m rod pulls and 6m inner tube runs

- Hydraulic mast dumping capability up to 2340mm, for ergonomic use

- -35° off horizontal (angle drilling) to 90° vertical down tilt capability

- 7,258kg capacity mainline hoist

- Field proven, patented nitrogen gas spring Nitro Chuck

- Hydraulic levelling jacks

- Can be set up on a small footprint